One of the defining aspects of this product is the high degree of customization it allows. Customers typically order this extrusion part in a variety of lengths and sizes, with each order encompassing at least 30 different specifications. The quantity for each length can range from as few as 50 pieces to as many as 1,000 pieces, necessitating precise production control. To accommodate these varying demands, the production process must include stable 45-degree bevel cutting, which is essential for achieving the clean, accurate edges required for both functionality and visual appeal.

Production scheduling plays a critical role in ensuring that each order is fulfilled efficiently and on time. With the diverse range of lengths and quantities involved, meticulous planning is required to manage the production flow effectively. This includes coordinating the cutting, surface treatment, and packaging processes to ensure that all components meet the customer's exact specifications. YUH FIELD, the manufacturer, has earned a strong reputation among its customers for its ability to maintain consistent quality and timely delivery, which are key factors in customer satisfaction.

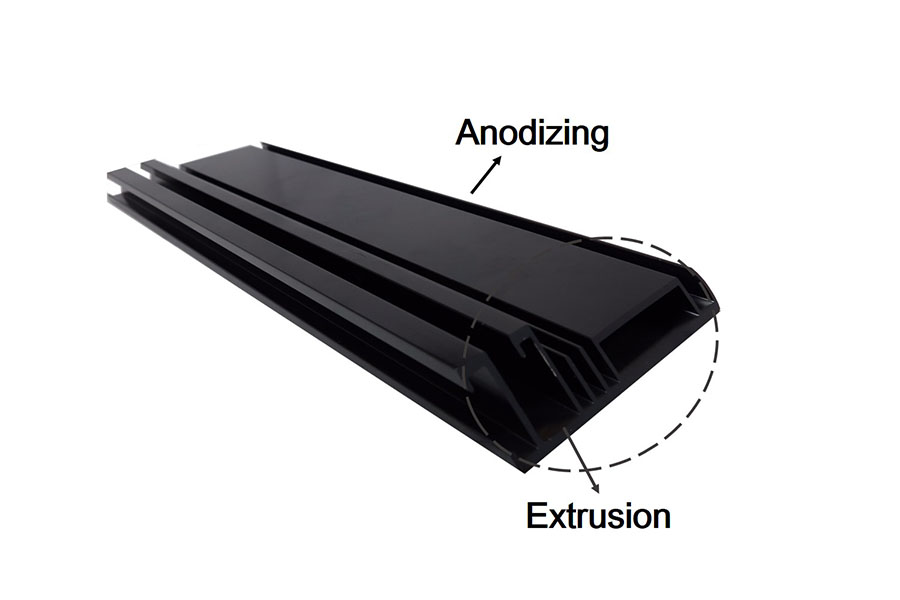

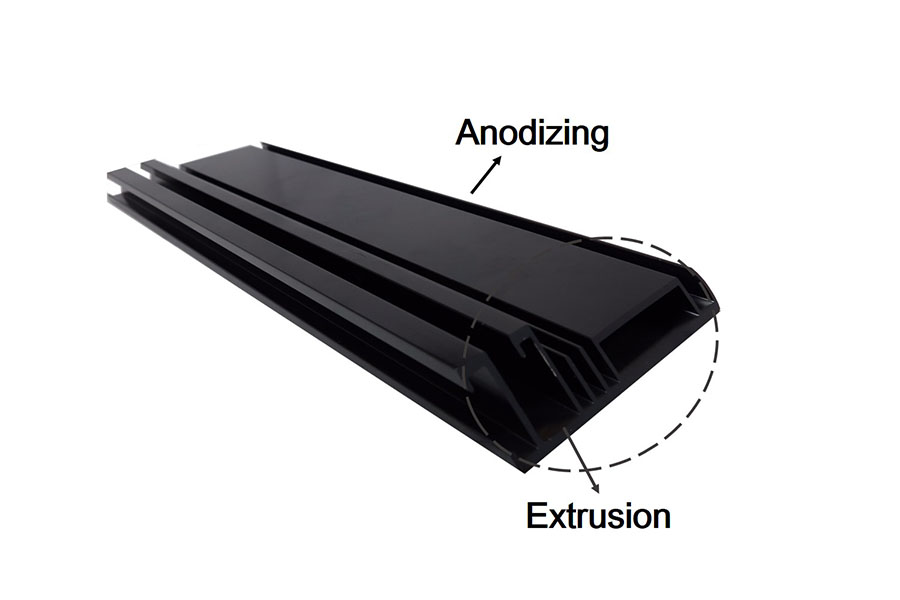

The product's appearance is of paramount importance, as it serves not only a functional role but also contributes to the overall aesthetic of the final installation. To achieve the desired visual effect, the surface of the aluminum extrusion part undergoes a brushed treatment followed by glossy anodizing in black. This dual finish not only enhances the product's durability but also provides a sleek, modern look that is highly valued in decorative applications.

Packaging is another crucial aspect that is tailored to the specific requirements of each order. Given the variety of lengths, different packaging methods are employed to ensure that each piece is securely protected during transit. This involves using custom packaging materials that prevent damage and preserve the product's pristine appearance. Additionally, clear labeling is implemented to facilitate easy identification and handling, further contributing to the efficiency and accuracy of the delivery process.

Finally, safe packaging is a top priority to ensure that the products arrive at their destination in perfect condition. This includes not only protecting the individual parts but also ensuring that the packaging is robust enough to withstand the rigors of transportation. The combination of clear labeling and secure packaging underscores YUH FIELD's commitment to quality, from production through to delivery.

※This product mold is owned by the buyer for reference only