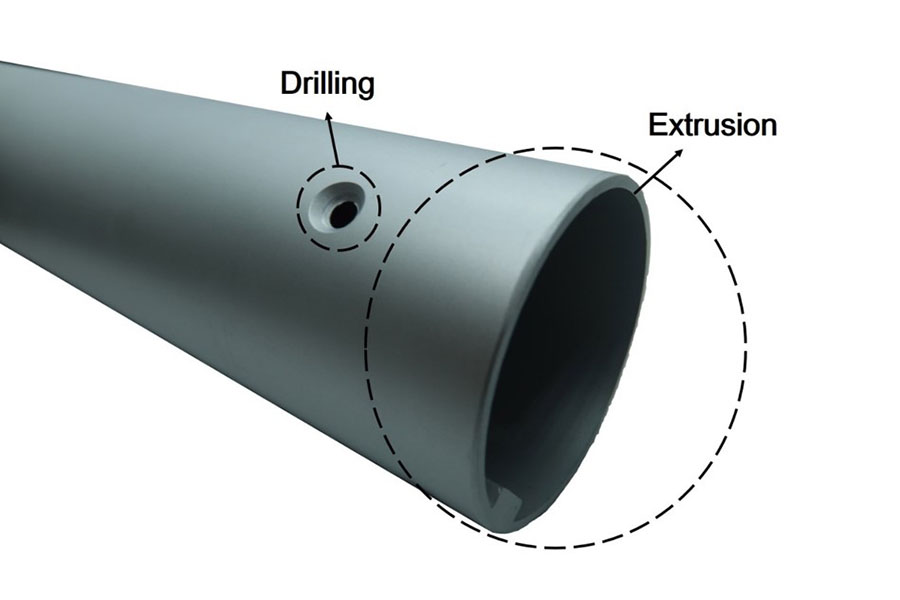

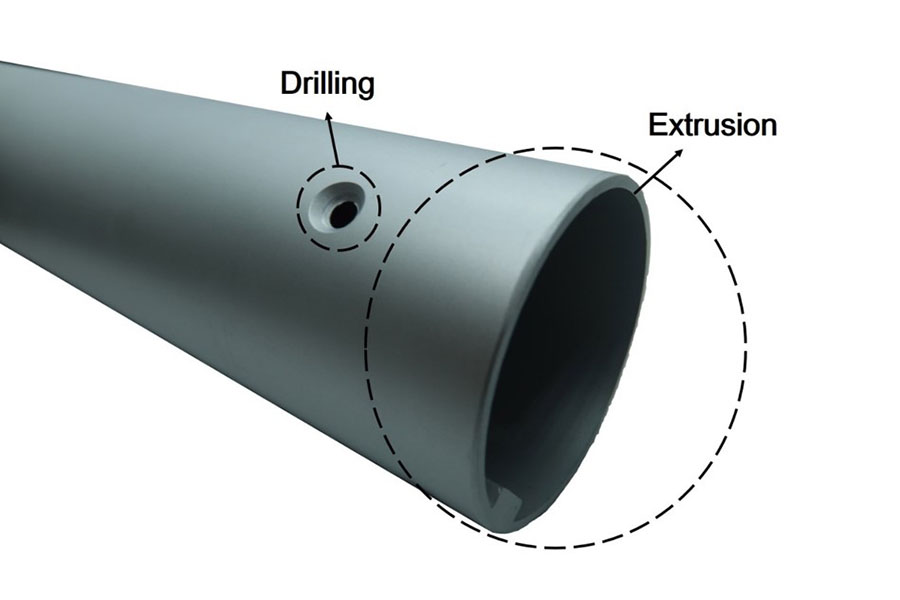

This seemingly ordinary round tube actually conceals a host of intricate details that reflect its precision engineering. The round tube has an outer diameter of approximately 34mm, and to ensure a seamless fit with external components and smooth operation, the aluminum extrusion is manufactured with a very tight tolerance of just plus or minus 0.15mm.The tube itself measures 650mm in length and features a screw hole necessary for assembly.

Notably, this screw hole can only be processed manually, not by machine, adding an extra layer of complexity to the production process. During this manual processing, it is crucial that the surface of the entire round tube remains completely free of any scratches or blemishes. The tube's surface is treated with a polished anodized finish, preserving the original color of the aluminum while enhancing its durability and aesthetic appeal.

This product is produced in significant quantities, with an annual order volume of around 20,000 tubes. The buyer is a Japanese company known for its rigorous quality standards, making the precise manufacturing of these tubes essential. The relationship with this buyer has been longstanding, with orders continuing for nearly a decade, reflecting a deep trust and consistent performance in meeting their stringent requirements.

※This product mold is owned by the buyer for reference only