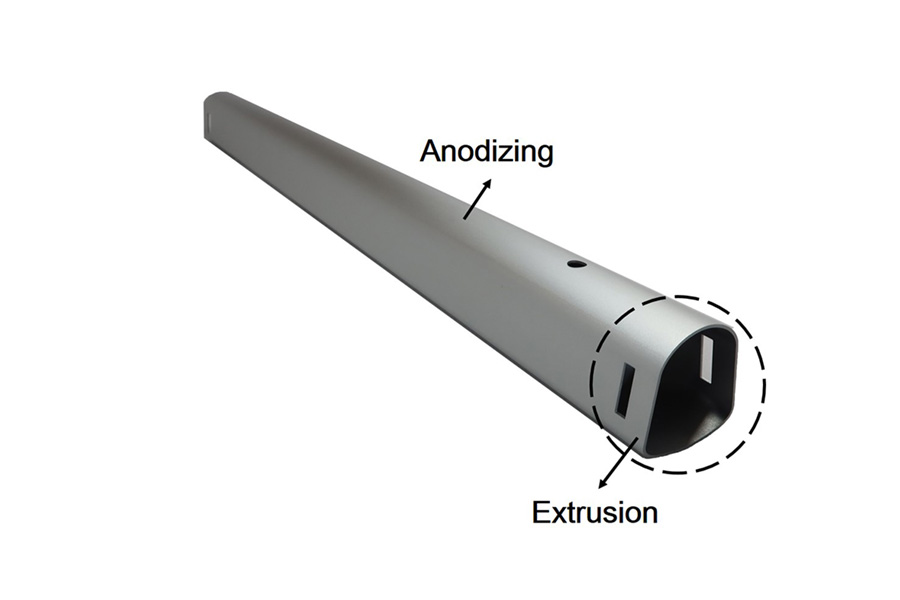

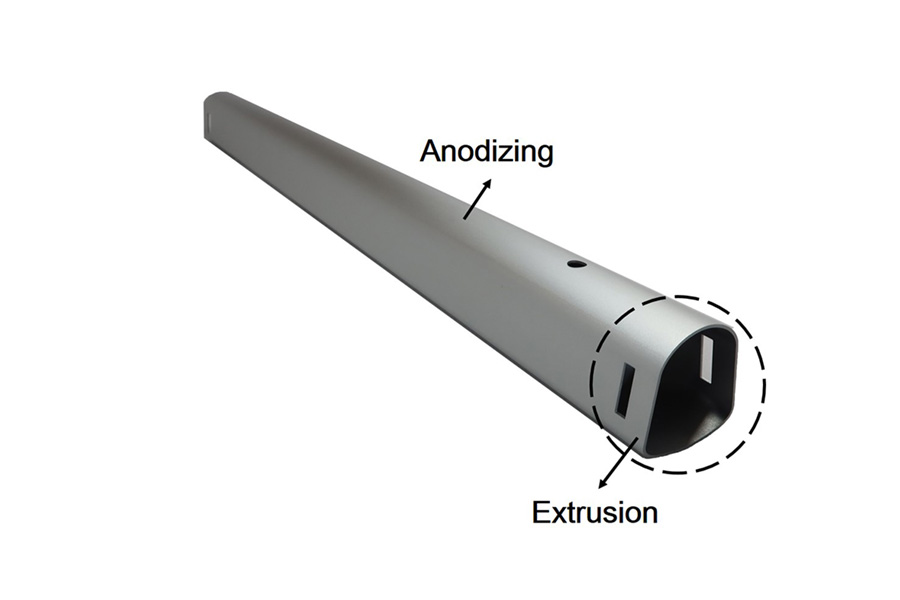

This customized aluminum extrusion part is specifically designed for the external pipe fittings of a vacuum cleaner. It is engineered to seamlessly integrate with various accessories and plastic injection connectors, making tolerance control a critical aspect of its production. To ensure that all components fit together perfectly, the inner diameter, outer diameter, thickness, and other processing dimensions of the aluminum extrusion are maintained with a tight tolerance of plus or minus 0.1mm. This precise control is essential for the smooth assembly and optimal performance of the final product.Given that this product is assembled by the buyer and sold directly to consumers (B2C), maintaining a high appearance quality is equally important.

The visual appeal of the part must meet the exacting standards expected by end-users, as any imperfections could impact the product's marketability and customer satisfaction.With an annual order volume exceeding one million units, this product demands not only meticulous manufacturing but also consistent quality across large-scale production. The high demand underscores the importance of maintaining the stringent tolerances and flawless appearance that are vital to the product's success in the highly competitive consumer market.

※This product mold is owned by the buyer for reference only