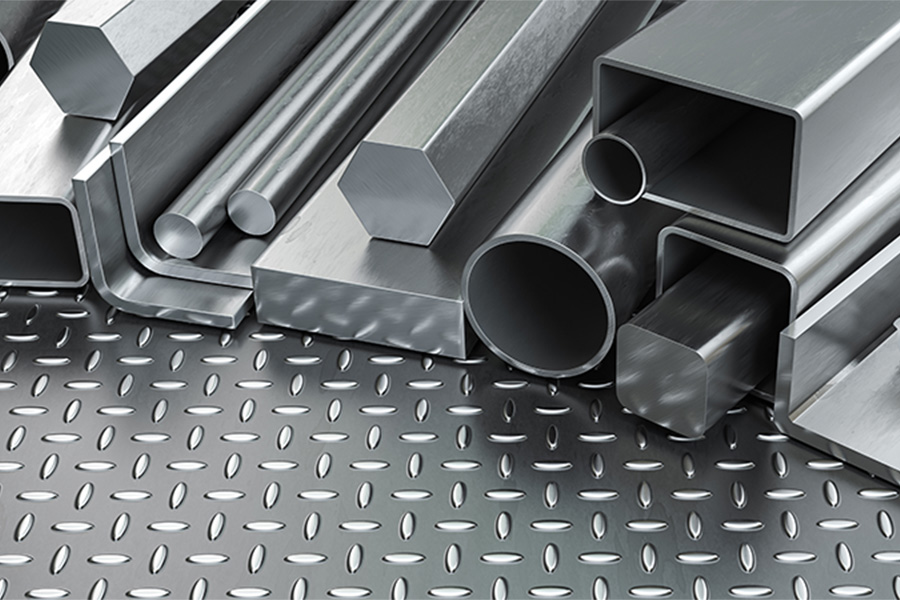

Understanding Aluminum Alloys: Types, Properties, and Applications

Aluminum alloys have become an indispensable material in modern industry due to their exceptional properties and versatility. From automotive manufacturing to aerospace engineering and even everyday consumer electronics, aluminum alloys are found in a wide range of applications. These alloys are not only lightweight but also offer excellent strength, corrosion resistance, and machinability. By adding different alloying elements, aluminum alloys can be optimized to exhibit specific physical and mechanical properties tailored to various application needs. In this article, we will explore the fundamental characteristics of aluminum alloys, the most common alloy series, and their applications across different industries, providing insights on how to choose the most suitable aluminum alloy for your project.

Key Alloying Elements and Their Effects

The unique characteristics of each aluminum alloy are achieved through the addition of different alloying elements. The type and quantity of these elements significantly influence the alloy's properties:

- Copper (Cu): Increases strength and hardness but can reduce corrosion resistance.

- Manganese (Mn): Enhances strength and improves resistance to wear.

- Magnesium (Mg): Provides strength and improves corrosion resistance, often used in combination with silicon.

- Silicon (Si): Lowers the melting point and improves fluidity, essential for casting applications.

- Zinc (Zn): Greatly enhances strength, especially when combined with magnesium.

- Lead (Pb), Tin (Sn), Bismuth (Bi): These elements are added to improve machinability, making the alloy easier to cut and shape during manufacturing processes.

The 6xxx Series: A Versatile Choice

One of the most popular and versatile aluminum alloys is the 6xxx series. This series primarily uses silicon and magnesium as its main alloying elements. The presence of these elements gives the 6xxx series a unique combination of desirable properties:

- Strength: The 6xxx series alloys offer moderate to high strength, making them suitable for structural applications. This strength can be further enhanced through heat treatment processes.

- Formability: These alloys can be easily shaped and formed, making them ideal for applications that require complex shapes and designs.

- Corrosion Resistance: The 6xxx series exhibits excellent resistance to corrosion, particularly in environments where other metals might degrade.

- Weldability: These alloys can be easily welded without losing strength or integrity, which is crucial for construction and automotive industries.

Due to these properties, 6xxx series aluminum alloys are used in a wide range of applications, including:

- Automotive components: Body panels, chassis, and engine parts. Construction: Structural frames, windows, and door frames.

- Aerospace: Aircraft structures and components. Consumer electronics: Housings and structural components for devices. Marine applications: Boat structures and fittings due to their corrosion resistance.

Choosing the Right Aluminum Alloy fo Your Application

When selecting an aluminum alloy, it's essential to consider the specific requirements of your project. Factors such as strength, corrosion resistance, formability, and machinability should guide your choice. For example, if high strength and good weldability are priorities, the 6xxx series might be the best option. However, for applications requiring enhanced machinability, an alloy with added lead, tin, or bismuth could be more suitable.

Understanding the properties and potential uses of different aluminum alloys allows manufacturers and engineers to make informed decisions, ensuring the success of their projects.

Ready to Choose the Perfect Aluminum Alloy for Your Project?

Selecting the right aluminum alloy can make all the difference in the success of your project. Whether you’re designing for strength, corrosion resistance, or ease of fabrication, understanding the unique properties of each alloy is key. Contact us today to discuss your specific requirements, and let our experts help you find the ideal aluminum alloy to meet your needs.

Get in touch with us now to start your project on the right track!