Aluminum Extrusion Machining: Benefits and Applications

Aluminum extrusion machining combines the advantages of aluminum’s versatility with precision machining techniques, creating highly customized components for a wide range of industries. This process enhances the functionality of aluminum extrusions by allowing for intricate designs, precise tolerances, and tailored performance characteristics.

What is Aluminum Extrusion Machining?

Aluminum extrusion machining involves two stages:

- Extrusion: Aluminum is forced through a die to create a profile with the desired cross-sectional shape.

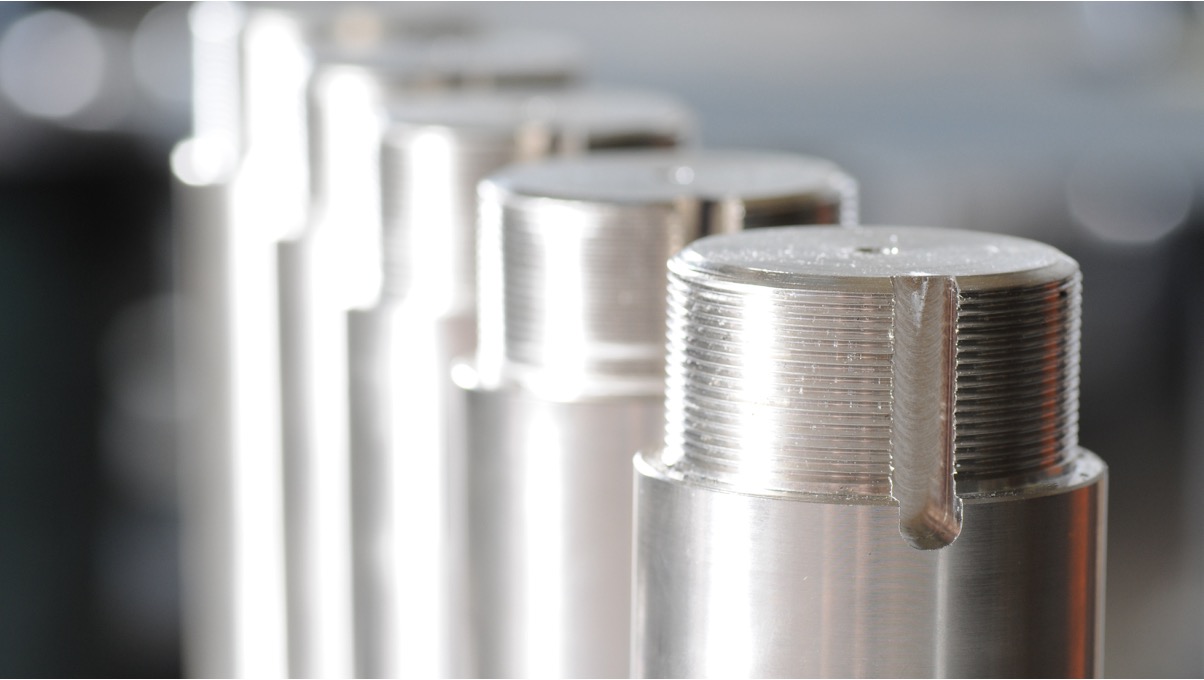

- Precision Machining: Advanced CNC machines refine the extruded profile by adding features such as holes, threads, and complex geometries to meet specific design requirements.

Our Service Process Machining

Aluminum extrusion machining shapes aluminum into precise profiles by forcing it through a mold and refining the product with advanced CNC techniques. This process creates high-quality components with smooth finishes and tight tolerances, ideal for industries like automotive, aerospace, and electronics. Whether using pre-extruded or specially selected aluminum, we tailor each product to meet unique specifications. Our custom aluminum machining services ensure that every component aligns with exacting standards, whether for aluminum extrusion machining or standalone aluminum machining services. We also partner with trusted aluminum extrusion suppliers to guarantee the highest quality raw materials for your projects.

Key Benefits of Aluminum Extrusion Machining

- Design Flexibility

The combination of extrusion and machining enables the creation of complex shapes and designs that are difficult to achieve with other manufacturing methods. - Precision and Consistency

CNC machining ensures tight tolerances, consistent quality, and high repeatability, ideal for high-performance applications. - Lightweight and Strong

Aluminum’s excellent strength-to-weight ratio allows for the creation of durable yet lightweight components, crucial in industries like aerospace and automotive. - Corrosion Resistance

Aluminum naturally resists corrosion, and surface treatments like anodizing or powder coating further enhance durability in harsh environments. - Cost-Effectiveness

The efficiency of extrusion combined with the precision of machining minimizes material waste and production time, resulting in cost savings for large-scale manufacturing.

The Machining Process

- Extrusion: Aluminum is forced through a die to create a profile with the desired cross-sectional shape.

- Precision Machining: CNC machines refine the extrusion, adding features such as holes, threads, and custom shapes to meet design specifications.

- Surface Treatment: Finishing processes like anodizing or powder coating enhance the aesthetic appeal, corrosion resistance, and durability of the final product.

- Quality Inspection: Rigorous testing ensures that all components meet required tolerances and performance standards.

Partner with Experts in Aluminum Extrusion Machining

At YF, we specialize in providing tailored aluminum extrusion machining solutions for industries worldwide. With state-of-the-art CNC machining capabilities and over 45 years of experience, we deliver high-quality, precision-engineered components that meet your exact requirements. As a trusted aluminum extrusion supplier, we ensure consistent quality and reliable sourcing for all your extrusion needs.

Contact us today to learn how our expertise in aluminum extrusion machining and aluminum machining services can elevate your next project.