The Role of Aluminum Extrusion in Machine Tools and the Mechanical Industry

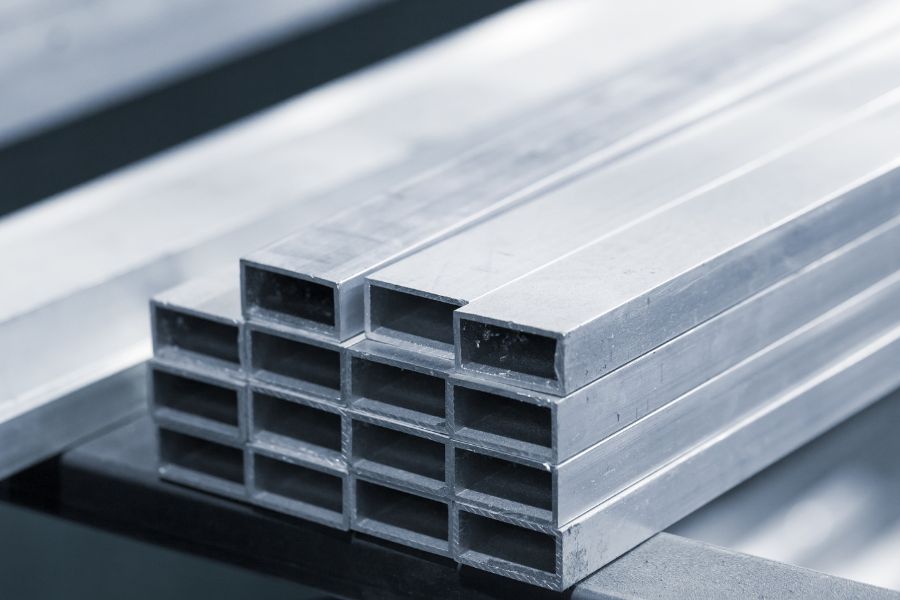

Aluminum extrusion has become an essential material in the machine tool and mechanical industries due to its lightweight, high strength, and versatility. Whether used in structural components, automation systems, or precision machining, aluminum extrusion provides significant advantages over traditional materials like steel.

With additional processing methods such as machining, anodizing, and laser engraving, aluminum extrusions can meet the high precision and durability requirements of modern mechanical applications.

Applications of Aluminum Extrusion in the Mechanical Industry

1. Machine Frames and Structural Components

One of the most common uses of aluminum extrusion in the mechanical industry is for machine frames and support structures. Due to its high strength-to-weight ratio, aluminum provides stability while keeping the overall weight low. Applications include:

- CNC machine enclosures and support structures

- Linear motion guide rails and modular framing systems

- Protective enclosures and safety barriers

Using aluminum extrusion in these areas makes assembly easier and more flexible, reducing installation time and costs.

2. Heat Dissipation Components

Heat management is critical in machinery, and aluminum’s excellent thermal conductivity makes it ideal for heat sinks and cooling systems. Common applications include:

- Heat sinks for servo motors and variable frequency drives

- Cooling systems in automation and industrial machinery

- Aluminum extruded radiator fins for thermal management

With anodizing, the surface of aluminum heat sinks can be further enhanced to improve heat dissipation and corrosion resistance.

3. Precision Machined Parts

Aluminum extrusion profiles can be further customized through CNC machining to create highly precise components. These include:

- Custom brackets and mounting plates for automation equipment

- Precision alignment guides and fixtures for assembly lines

- Motion control components such as linear rails and sliders

The ability to machine aluminum to tight tolerances makes it an excellent material for applications requiring both high precision and durability.

4. Automation and Robotics Applications

Aluminum extrusion is widely used in automation and robotic systems, thanks to its lightweight nature and modular design. Some key applications include:

- Robot arm structures and frames

- Linear actuator housings

- Cable management channels in automated production lines

The ability to customize aluminum extrusion profiles allows manufacturers to design modular automation solutions that are easy to assemble and reconfigure as needed.

5. Fluid and Pneumatic Systems

Aluminum extrusion is also used in fluid handling and pneumatic applications, particularly in components such as:

- Hydraulic cylinder housings

- Pneumatic actuator bodies

- Pipe and conduit support structures

With anodizing, these components gain additional protection against wear and corrosion, extending their lifespan in harsh industrial environments.

Advantages of Using Aluminum Extrusion in Machinery

- Lightweight and High Strength

Aluminum extrusion provides excellent structural integrity while being significantly lighter than steel. This reduces the overall weight of machinery and improves efficiency, especially in automation and motion control systems.

- Corrosion Resistance

Through anodizing, aluminum extrusions gain an oxide layer that enhances their resistance to wear and environmental damage, making them ideal for long-term industrial use.

- Precision Machinability

Aluminum is easy to process using CNC machining, allowing for the creation of highly accurate parts with minimal material waste. This is crucial for applications requiring exact tolerances.

2. Modular and Easy to Assemble

Aluminum extrusion systems are often designed for modularity, making them easy to install, adjust, and expand. This reduces assembly time and costs for manufacturers.

3. Excellent Heat Dissipation

With its natural thermal conductivity, aluminum extrusion is ideal for heat dissipation applications, ensuring that industrial equipment remains cool and operates efficiently.

Aluminum extrusion is transforming the machine tool and mechanical industries, offering lightweight, durable, and customizable solutions for various applications. With additional processes like machining and anodizing, aluminum components become even more versatile, providing excellent performance in automated systems, precision instruments, and industrial machinery.

As manufacturing continues to evolve, the use of aluminum extrusion will only grow, providing cost-effective and innovative solutions for modern industry.

If your business is looking for high-quality aluminum extrusion solutions with precision machining and anodizing, partnering with a trusted manufacturer can ensure that you receive the best materials tailored to your needs.